Home » Custom Wine Cellar Cooling – Problems

The 4 Main Problems with Wine Cellar Cooling Systems & How to Avoid Them

Custom Wine Cellar Cooling – Problems

Problem #1 – Lack of a Correctly Installed Vapor Barrier

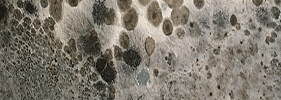

This is a common problem, certainly unpleasant, and probably the most costly to remedy. When a vapor barrier is not installed in just the right way, mold is usually the result. Mold due to excessive humidity created by the temperature difference between the outside of the cellar and that maintained in a wine cellar is both insidious and hidden. By the time most people notice they have a problem it can be deep in the walls and ubiquitous. The reason this happens is that humidity (water in the air) is directly affected by temperature. Warmer air holds more water, cooler air holds significantly less. This is why dew can be seen on a lawn in the morning. As the air cools overnight the water accumulated in warm air during the day is forced to attach itself to any available surface.

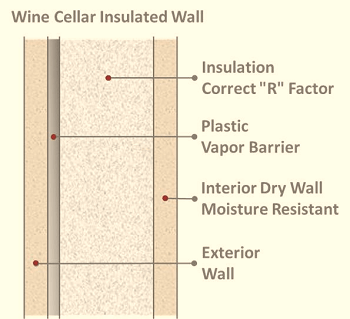

The way a wine cellar is cooled can inherently promote moisture migration: this means it is pulling moisture in from surrounding rooms or from the outside environment. The extent of this problem will of course vary from location to location and from one season to another as the outside humidity levels vary. With a correctly installed vapor barrier, this process is halted. If a vapor barrier is not installed and mold does appear it can be necessary to completely remove the drywall from the walls and the ceiling. The insulation will then need to be removed, possibly even replaced. To correctly install a vapor barrier it is applied first, against the outside wall, then the insulation is inserted and lastly, the drywall is applied.

As you can imagine, in a wine cellar full of racking, the process of removing everything to apply a vapor barrier to the outer walls and ceiling of the room is no small task. It’s not unusual for an inexperienced wine collector to consider building a wine cellar initially without a wine cellar cooling system with the intent of adding one later if they perceive the need.

The reason this can be a mistake is that when the wine cellar is not designed from the beginning to be a climate-controlled environment, details such as vapor barriers are often overlooked. This requires them to be retrofitted when the refrigeration system is installed. A regular builder or HVAC engineer, not experienced in the construction of custom wine cellars, will often happily install a cooling system and while the cooling system may work fine, a year two later, the disaster called mold strikes the unsuspecting owner.

Problem #2 – Poor or Partial Insulation

This problem is pretty straight forward in as much as the consequence is obvious. If the wine cellar insulation is not of a sufficient rating (“R” factor) or it is poorly applied or not applied to all the walls and ceiling, the result can be fluctuating temperatures, a cooling system being over worked, running continuously, being excessively noisy and possibly even failing. When we have seen problems with cooling systems breaking down this is often the underlying cause. Remedying this problem, while not as severe as a problem with mold, can still be a big deal requiring walls or ceilings being removed.

Problem #3 – Wine Cellar Doors not Completely Sealing the Room.

Custom Wine Cellars Doors are purpose-built to seal the wine cellar. They are specially constructed to insulate, seal and reduce the probability of warping due to humidity and temperature differences maintained in the wine cellar. As well as their special laminated (warp-resistant) construction, they have a special method of sealing the bottom of the door through a mechanism that seals the gap between the threshold and the door bottom when it is closed but retracts as the door opens. This helps to ensure that the seal does not degrade with use and because it retracts automatically when opened, it does not damage your floor. If the right kind of door is not fitted this can lead to outside air creeping into the wine cellar around the door rather than through the refrigeration system which can cause moisture creep and the cooling system running overtime to compensate.

Problem #4 – The Wrong Type of Wine Cellar Lighting.

Lighting in a wine cellar is the final touch of finesse that can really make a wine cellar look outstanding. The use of cans, spots lights, and concealed lighting effects, that highlight sections of the wine displays, is a great addition that dresses up the wine racking itself.

Problems can arise when wine cellar lighting is chosen that produces heat. It should not be underestimated how much heat lighting can produce. In a typical room where the air is circulated throughout a home or commercial building, this is not normally noticeable. However, in a sealed wine cellar, which is usually a comparatively small room, adding some lighting can be extra special but if it is heat-producing lighting then problems can occur.

To avoid these issues but still create a beautifully lighted wine display, we recommend low heat output LED lighting fitted with timer switches. We recommend the timers because wine cellars usually only have occasional use or are classed as a storage room. This means it is not unusual for lighting if it is left on, to be on for many days or even weeks at a time between visits.

Your Wine Cellar Climate Control System – An Integrated Whole.

It is for these reasons that when designing a wine cellar, we believe the climate control system should be considered an integrated system. An integrated system should be designed into the wine room from the beginning and not a process of simply adding a wine cellar cooling unit to a wall, somewhat arbitrarily, without its full impact being considered.

If you live on the opposite coast to California in a high-risk area such as Miami Florida contact Wine Cellar Cooling Services Miami and get one of their maintenance plans. It will save you money and heartache in the future. Wine Cellar Cooling Services Miami Florida.